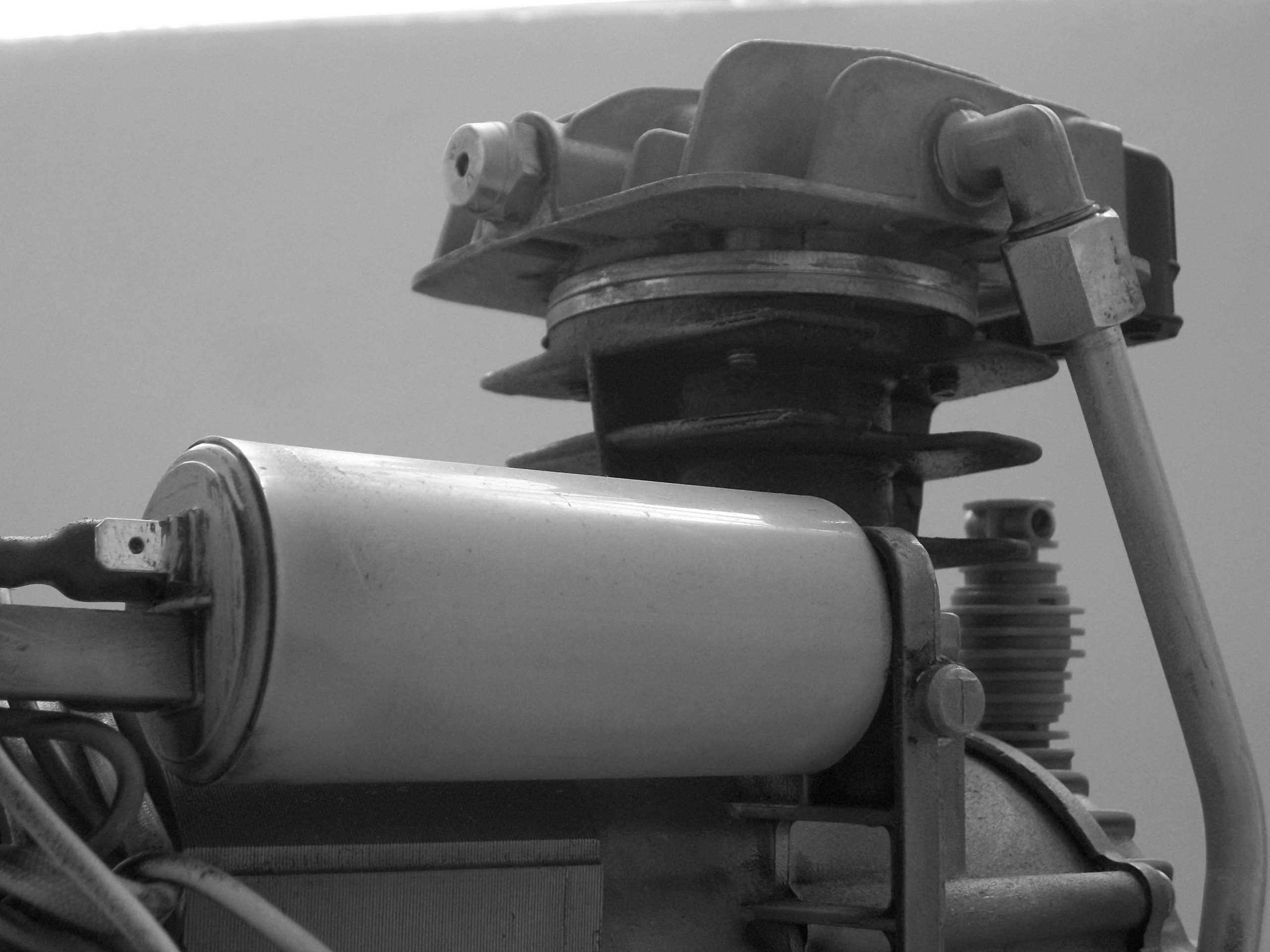

The Guide to Understanding Air Dryer.

If you work in a telecommunication company or a dental office, you’ve definitely heard of an air dryer. No, not a hairdryer, but an air dryer. Most of us are familiar with the former, while very few of us know what an air dyer is or its function. This is a necessity for the success […]